Focused Case Case Study of Retrofitting Garbage Truck

- Home

- Focused Case

- Retrofit of Garbage Truck

Retrofit of Garbage Truck

- Retrofit of Garbage Truck

- EPA Taipei supported experimental project of retrofitting garbage truck organized by EPA Taiwan to assess performance of particulate filter. EPA Taipei took a lead to retrofit 50 Euro III garbage trucks by installation of particulate filter in 2015.

- Operation mode of Garbage Truck

- Garbage truck is operated with frequent idling when collecting garbage but running at high speed when job being done.

- Operation mode of garbage truck includes frequent idling, low driving speed and low exhaust temp. which must be paid attention and understood fully before particulate filter being sized, and strategy of filter regeneration being selected.

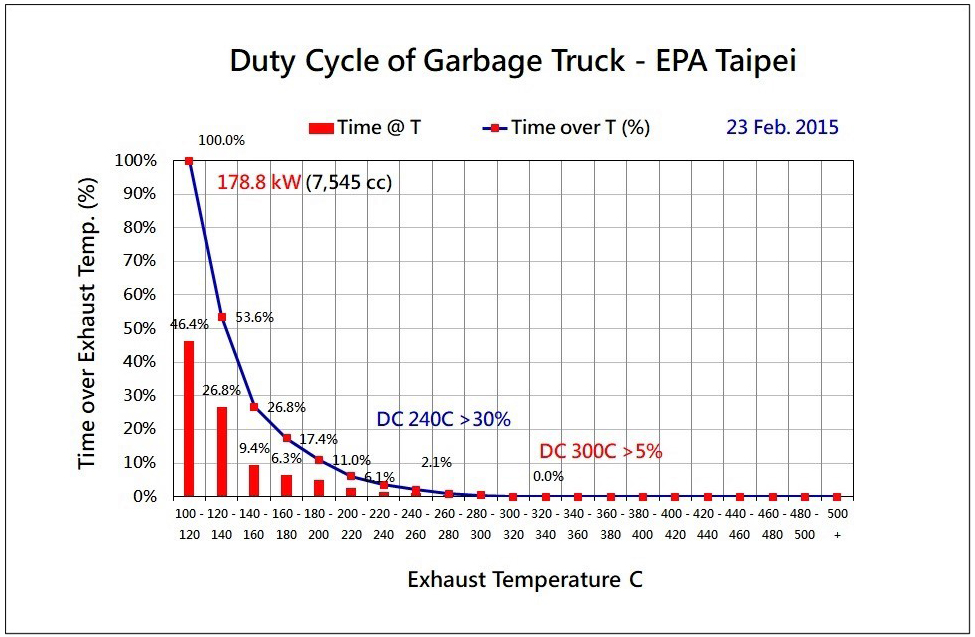

- Duty Cycle Assessment (DCA) of Garbage Truck

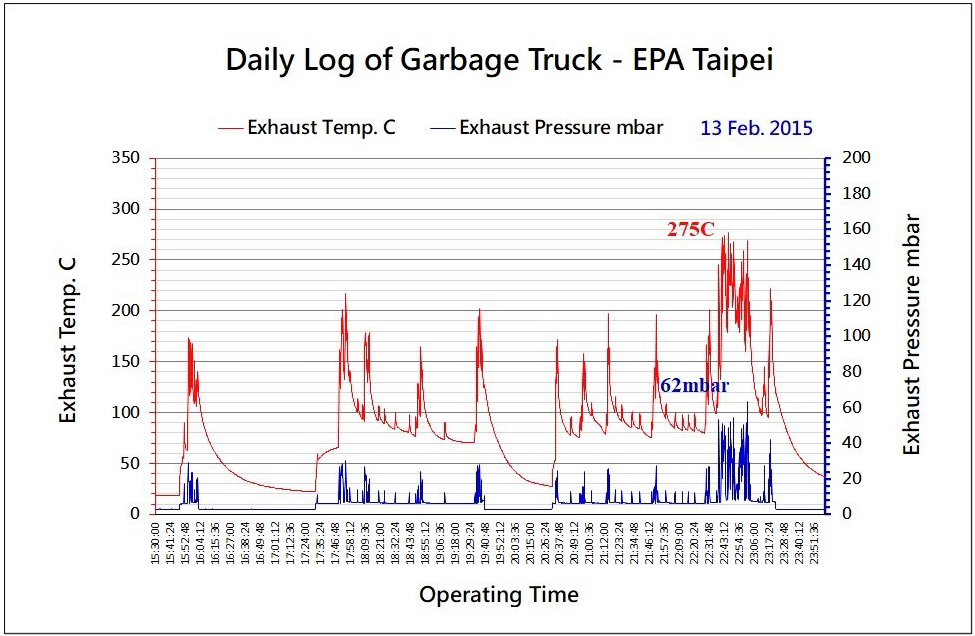

- Daily log of exhaust temperature and pressure after filter installed.

- Duty cycle analysis as blow shows profile of exhaust temperature over time in % of daily operation of garbage truck.

- 2.10% of duty cycle, exhaust temperature >240C.

- 0.00% of duty cycle, exhaust temperature >300C.

- Strategy of filter regeneration: Dual Filter Regeneration.

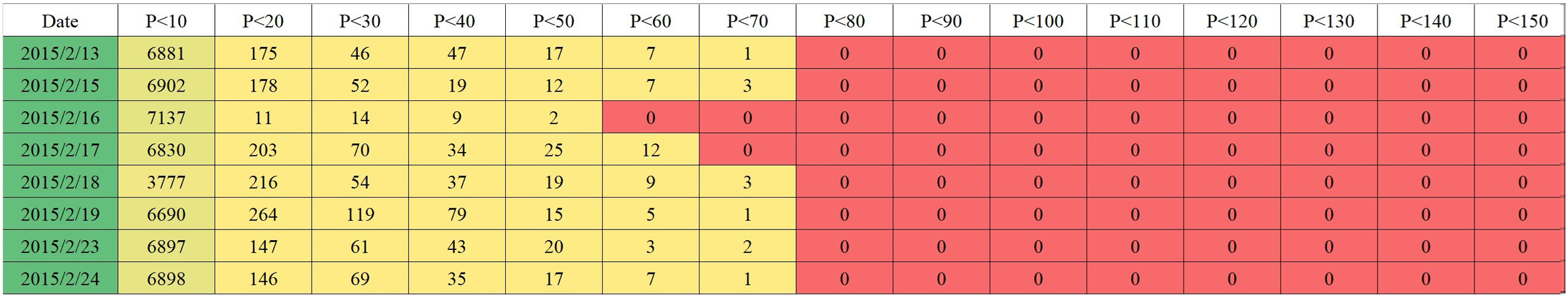

- 8 days log of exhaust pressure after filter installed of garbage truck.

- 8 days operation log of retrofitted garbage truck with active particulate filter and supportive electrical heater for regeneration, shows maximum exhaust pressure is 70 mbar, which is lower than alarm setting that confirmed the design.

- Particulate filter of retrofitted garbage truck of EPA Taipei is regenerated by supportive electrical heater biweekly to ensure filter is cleaned.

- Retrofitted garbage trucks of EPA Taipei was subsidized by EPA Taiwan, and is the only project that runs more than five years in Taiwan since 2015.

- About Us

- About Us

- Patents

- EPA Approval

- Key Customers

- Key Customers

- Key Reference

- Awards

- Focused Case

- Login

- Contact Us

- About Us

- Target Market

- Products

- Key Customers

- Login

- Contact Us