Retrofit of Shuttle Bus

- Retrofit of Shuttle Bus

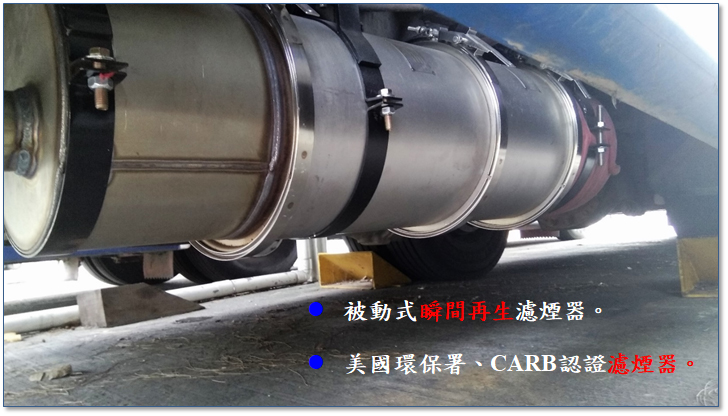

- The Refining Business Division of CPC supports policy of EPA Taiwan, that prioritize emission reduction by retrofitting vehicles in the Kaohsiung Area. Headquarter of Refining Business Division of CPC took the lead in Nan Zi District, that all shuttle buses of Refining Division were installed particulate filter since 2017.

- Operation Mode of Shuttle Bus

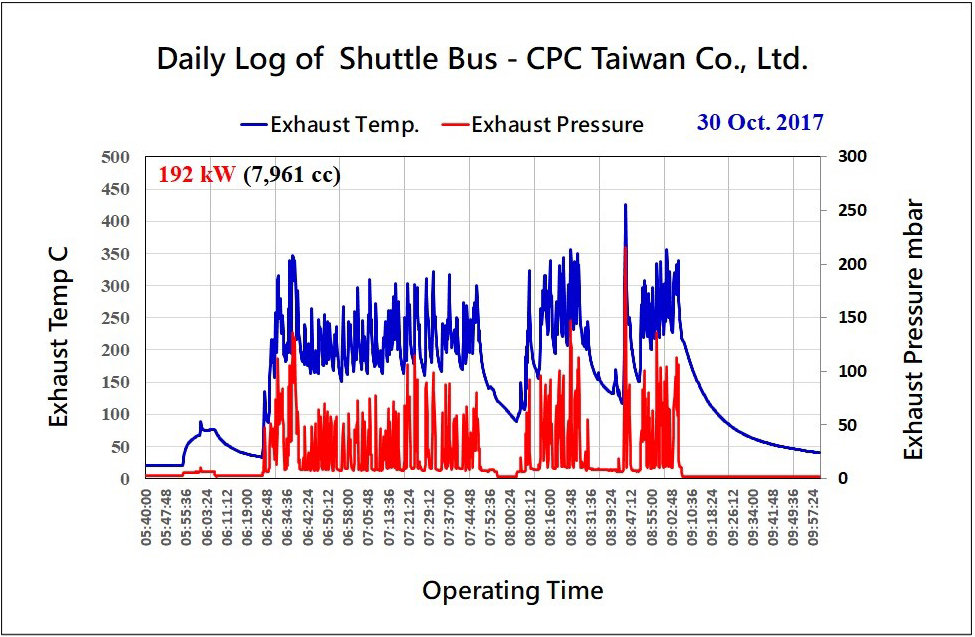

- Shuttle bus of Refining Division of CPC departs from Headquarter of Division at 6:50 every morning to Refinery Site. The journey is about 27 km, which takes 1 hour, the shuttle bus runs 4 times per day.

- The journey of shuttle bus is not only very short in distance, but also in driving time as well, which is a typical driving mode of low average speed, short distance, and frequent engine idling, that requires more caution when selecting strategy of filter regeneration and sizing of particulate filter due to low exhaust temperature.

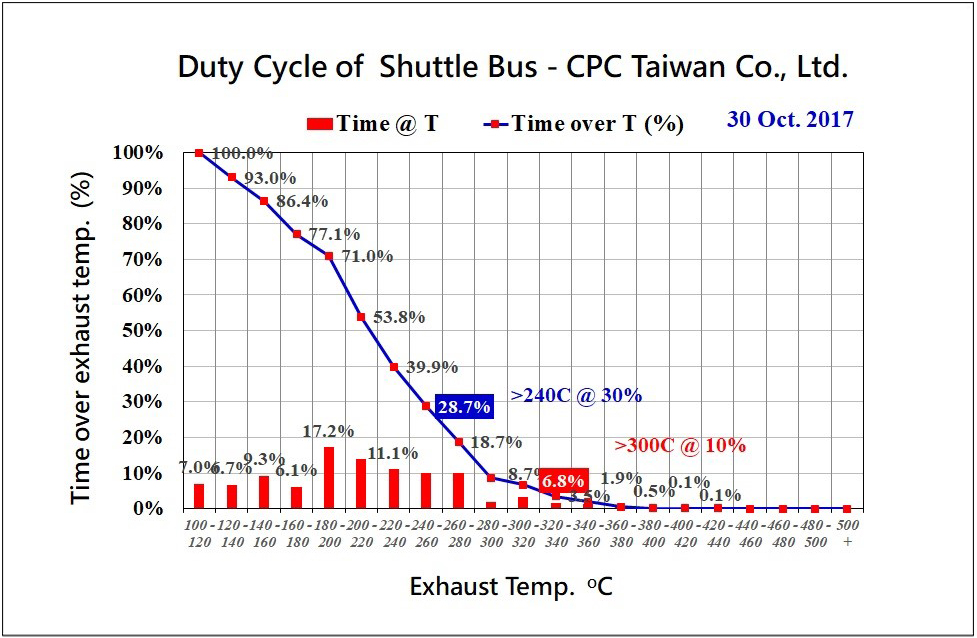

- Duty Cycle Assessment (DCA) of Shuttle Bus.

- Daily log of exhaust temperature and pressure after filter installed.

- Duty cycle analysis as blow shows profile of exhaust temperature over time in % of daily operation of shuttle bus.

- 28.7% of duty cycle, exhaust temperature >240C.

- 6.8 % of duty cycle, exhaust temperature >300C.

- Strategy of filter regeneration: Continuous Filter Regeneration.

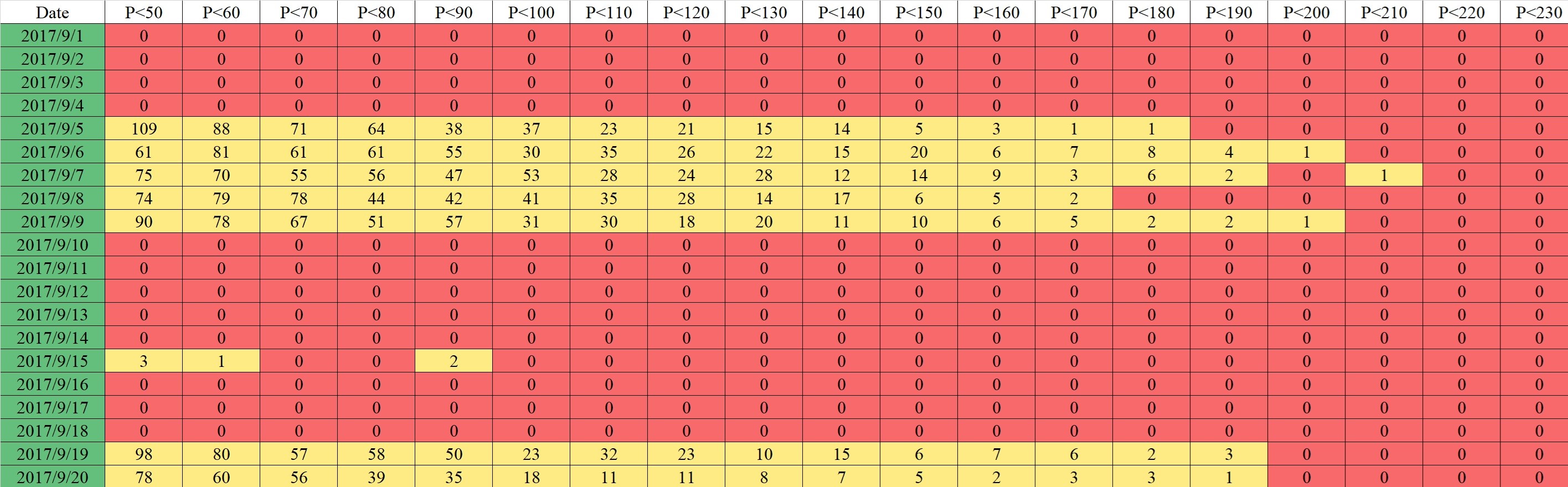

- 20 days log of exhaust pressure after filter installed of Shuttle Bus.

- 20 days log of shuttle bus after filter installed shows maximum exhaust pressure is 210 mbar, which is lower than the BP alarm setting, that proves continuous regeneration of filter has been successfully achieved and performing well.